And if we expanded the color palette...

Carefully selected raw materials, a little know-how, and a lot of patience…

Working with materials and the colours of the Living through a range of attractive, saturated or soft, rich and deep shades which harmonize wonderfully well with each other.

Renew and perpetuate practices that have spanned centuries, civilizations and traditions, while adapting to current developments and concerns.

Natural dyeing is a craft that has its own technical rules.

In order to develop the color palette and create durable works, it is interesting to deepen one's practice through knowledge and mastery of various processes.

Natural colors made by hand from plants, insects or natural extracts

Natural dyes come in two forms: raw materials, fresh or dried, coming directly from the source (a plant, a fungus, a lichen or an insect) and extracts, fine powders or liquids, which are concentrated derivatives of these natural materials.

The workshop uses various sources of dyeing materials from:

– Crops from local production, controlled and sustainable sectors.

– Specialized shops and herbalists.

– Pickings in the garden or during walks.

– Recovery of green waste.

– 100% natural plant extracts, GOTS 6.0 certified (used in a few specific cases, particularly when the desired color is not available locally).

Young spring leaves in the garden, small, light and delicate summer flowers, invasive and prickly brambles and nettles, autumnal treasures hidden in the woods or exotic discoveries during adventures at the end of the world... thank you.

A diversity of fibers, 3 types of dyes, a variety of processes

– Tannins for black, gray, beige, brown…

– So-called “mordant” dyes for – reds, yellows and composite colors.

– Indigo, blue extract.

Do not confuse pigments and dyes

From dye plants or insects, we extract by decoction water-soluble dyes. Several processes allow to dye the fibers durably by immersing and cooking them in these colored baths.

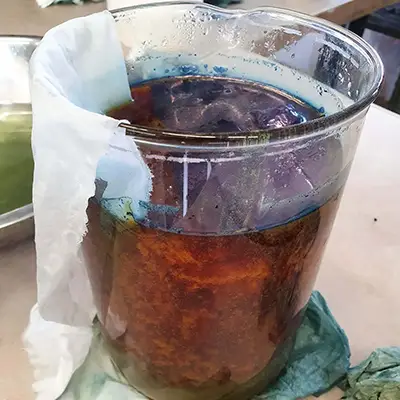

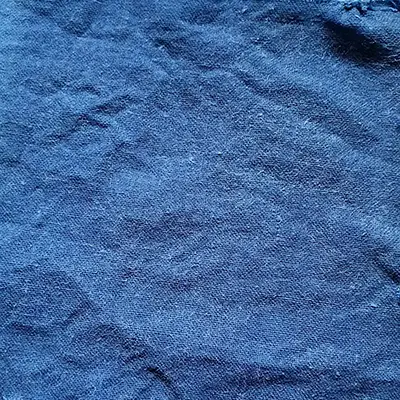

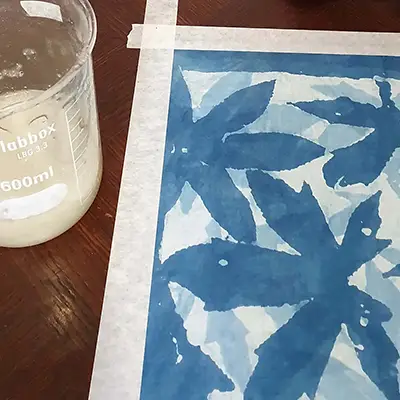

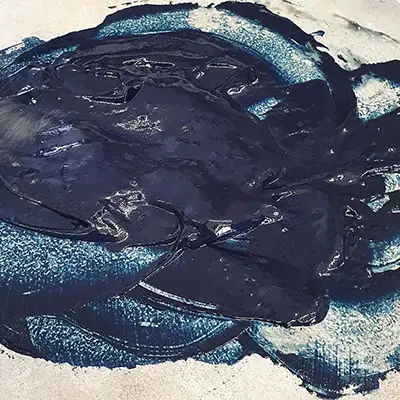

Indigo, a world apart

Indigo is a pigment and not a dye. It is therefore not soluble in water.

It does not exist as such in so-called indigo plants. It must be extracted using a specific process that is more complex than a simple decoction. Intense blue, this indigo pigment is made soluble in an alkaline vat and reduced in oxygen. Successive soakings of the fiber to be dyed in the indigo vat, interspersed with exposure to air, allow the fibers to be directly dyed into a blue that is solid in the light and when washed. The workshop uses a 100% natural indigo vat.

An infinity of colors

Each dye is unique, the colors are never identically reproducible. Fibers like dye materials are directly connected to nature and the seasons.

Many elements influence the result: the type and quality of fibers, the plant used (place and method of cultivation, type of soil, growth variations, weather, etc.), the quality of the water (pH), the temperature and cooking time, the processes used to dye, etc.

Natural dyeing is therefore an exploration, a source of wonder and constant surprises.